About Product

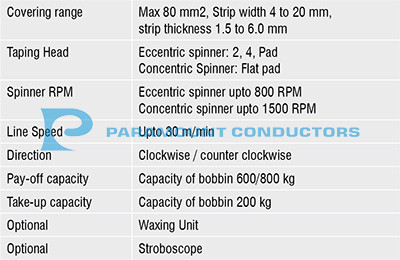

NEXGEN High-Speed Servo-Controlled taping lines is used for taping Insulating paper, Nomex, PET, Mica, Kapton etc. on round or rectangular wire that are used in winding of Motor, Generators, Transformers etc. The machines is modular in design with Payoff, 1, 2 or more concentric or tangential taping heads, Caterpillar or Capstan, and take up. The modular construction enables a wide range of flexible configuration in Taping machines.

Pay-off: Pay-off supply is designed for quick loading and unloading of reel. Optional motorized lifting/lowering of bobbin.

Collapsible Straightener: Collapsible straightener consists of Hardened rolls and is used to maintain the wire in straight direction without any axial deviation.

Motorized Wiper Unit: Motorized rotating wiper is used for cleaning bare wire. Optional vacuum dust collector can be provided.

Taping Units:

• Eccentric spinner is designed for 2 or 4 tape pads with constant tension arrangement from start to end of tape. Photo sensor for tape breakage detection & stoppage.

• Concentric spinner is designed for traverse wound or flat pads.

Caterpillar/Capstan Unit: Caterpillar is Servo motor driven and synchronized with spinner speeds for consistent lapping and to maintain constant linear speeds.

Take Up: Torque motor driven Take-up traverse with step-less pitch control with roll-ring or optional Reel Traversing. Lifting and lowering of bobbin by motorized gearbox.

Control Panel:

• Panel for PLC & Drive with built in Ethernet connectivity for remote maintenance over Internet.

• Easy to operate HMI (Human Machine Interface) for programming parameters like tape lap percentage, line speed, wire size etc. The system is designed to store all data for easy recall for future use and also to transfer data to internal network.