About Product

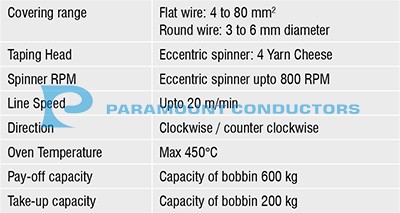

NEXGEN High-Speed Servo-controlled Fibre Glass Spinning and Varnishing Line is designed to insulate round or rectangular wire with Glass/Daglas® yarn and impregnating with varnish and curing in oven. The spinner is designed to maintain constant yarn tension throughout its length from start to end. It is synchronized with capstan to maintain constant linear speeds.

Pay-off: Pay-off supply stand is designed for quick loading and unloading of reel.

Collapsible Straightener: Collapsible straightener consists of hardened rolls and it is used to maintain the wire in straight direction

without any axial deviation.

Motorized wiper unit: Motorized rotating wiper is used for cleaning bare wire

Fibre Glass/Douglas Spinner:

• Servo motor driven 2 eccentric spinners with each having 4 yarn cheeses is designed to have constant yarn tension throughout its length.

• Serving point, the point at which the yarn meets the wire can be adjusted. The lapping is adjustable using lapping adjuster.

• Auto stopping of machine on yarn breakage or when yarn ends or is loose

• Varnish Applicator is consists of felt wiper for suitable coating of varnish and for removing excess varnish from the conductor before curing operation in ovens.

• Optional Strobe light for freeze frame view of spinning

Taping Unit: Optional Taping unit can be incorporated in the machine for insulating wire in combination with Glass/Daglas® yarn and PET film.

Hauling Unit: Capstan is Servo motor driven and is synchronized with spinner rotation to precisely control linear speeds and wire tension.

Curing Oven: Ovens for sintering process are pneumatically operated for automatically opening and closing during start-stop phases or when the yarn breaks.

Cooling System: Aluminium guide pulleys are provided for additional cooling of glass/Daglas® covered wire. Cooling system consists of blower for stabilizing strips/wire coating and cooling the guide pulleys.

Take Up: Torque motor driven Take-up traverse with step-less pitch control with roll-ring or optional Reel Traversing. Lifting/ lowering of bobbin by motorized gearbox.

Control Panel:

• Panel for PLC & Drive with inbuilt Ethernet connectivity for remote maintenance oven Internet.

• Easy to operate HMI (Human Machine Interface) for programming parameters like wire size, yarn selection, line speed, length counter, temperature setting etc the system is designed to store all data for easy recall for future use and also to transfer data to the internal network.