About Product

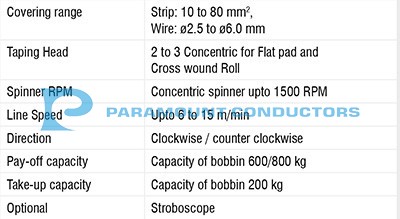

NEXGEN High-Speed Servo-Controlled Kapton taping and Sintering lines is used for taping Polyimide-FEP (APICAL®), Kapton®, Norton® etc. on round or rectangular wire that are used in winding of AC Traction Motors etc. The machines is modular in design with Payoff, 1, 2 or more concentric or tangential taping heads, Caterpillar, Induction Pre-Heaters, Curing ovens, Cooing System, Spark Tester and Reel traversing take up.ing on the cross section area of the strip. In each pass there shall be one reduction/finishing operation.